Release time:2023-07-20

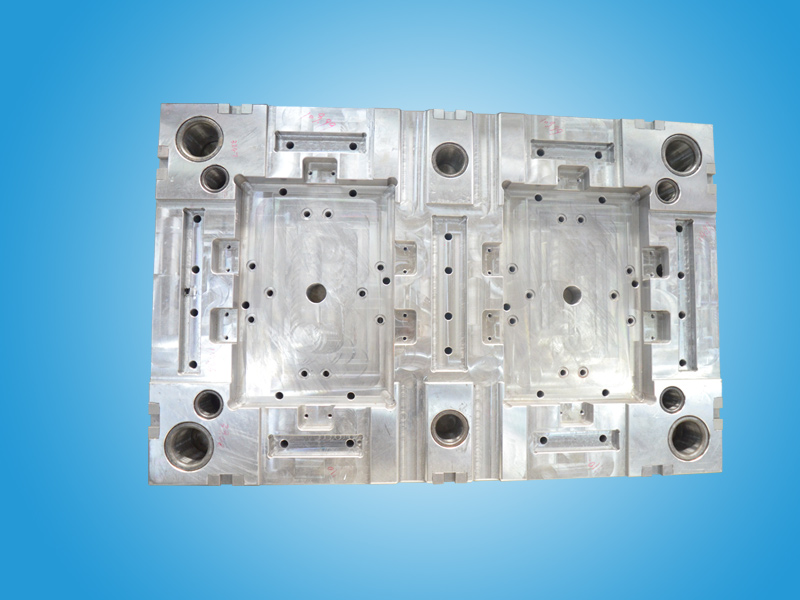

Injection mold inserts are also called inserts, and some people call them inserts, which are called differently. It refers to the mold accessories used to inlay the core of injection mold, which requires high precision. So why in injection moldingMold processingIt takes time to make inserts?

Mainly for the following purposes:

1. Save the manufacturing materials of injection mold

As we all know, the fixed material of the injection mold is regular block steel with fixed shape, but the material of the front and rear mold is determined by the height. Whether it is the front mold or the rear mold, if one place is higher than other places, inserts can be made to reduce the height of the mold.

2. Convenient mold change

Where the injection mold is often modified, it can be removed to make inserts. When changing the mold in the future, only the inserts need to be replaced, and even when opening the mold, several more inserts can be replaced, so it is convenient to modify the mold.

3. Conducive to injection mold exhaust

The exhaust of injection mold is very important. If the exhaust is not good, there will be trapped air in the mold cavity, especially in the deep bone position. In the process of injection molding, the product is prone to bubble or shrinkage, lack of glue, whitening or black spots and other adverse information. Therefore, you can add inserts where the mold needs to exhaust, and use the fitting gap of the inserts to exhaust.

4. Convenient for injection mold processing

There are some deep bones in the injection mold, and the tool is difficult to machine. Although EDM can be used, the speed of EDM is slow and the processing efficiency is low. Therefore, it is generally selected to make inserts, which reduces the processing difficulty and facilitates the exhaust. Another is the deep bone type formwork saving, because it is very inconvenient to save the formwork where it must be removed, but it is much more convenient to open the inserts in these places.

5. Extend the service life of injection mold

Generally, the place where the injection mold needs to design inserts is also the place where the mold is easy to be damaged. Once the insert is damaged, it can be replaced, thereby extending the service life of the injection mold.